elliTek's Automation Know-How

elliTek's Automation Know-How is a quarterly podcast that takes you beyond the buzzwords to explore how real automation solutions are applied in real manufacturing environments. Hosted by Brandon Ellis, owner of elliTek and automation expert, each episode dives into the practical side of industrial automation — from hardware and software to integration strategies and IIoT — all grounded in how these technologies work on the factory floor.

Whether you're an engineer, plant manager, or just automation-curious, you’ll gain actionable insights and a clearer understanding of the technologies shaping modern manufacturing.

New episodes every quarter — follow now and build your automation know-how.

elliTek's Automation Know-How

Industrial Automation - It Doesn't Have To... Lag

This episode is dedicated to the Edge - Edge Computing that is. Listen to learn all about Edge Computing. What is the Edge? Where is the Edge? What's the big deal?

Brandon gives a down-to-earth explanation of what the edge is outside of manufacturing that nearly everyone can relate to.

Find out what lives on the Edge in the world of manufacturing. Learn the differences between smart and intelligent devices.

Discover the differences between product data and process data and how these types of data relate to edge-based computing.

Hear how edge computing can be used in new applications, as well as existing architecture.

Learn how elliTek's Team helped a manufacturer use edge computing to save time and resources.

Stay tuned for Brandon's Brandology along with some advice for manufacturers looking to utilize edge computing.

Here are some links that were referenced during the show.

ISA levels

TEEP episode

IoT Doesn't Have To Be Overwhelming episode

5 Stages of IoT Grief video

Brandon Ellis 0:24

Hey, everybody, this is Brandon Ellis, your host of "Industrial Automation - It Doesn't Have To", and I am here with the lovely Beth Elliot. Hey, Beth.

Beth Elliott 0:34

Hey, Brandon, good day to you.

Brandon Ellis 0:36

You know, I'm kind of fired up, Beth. And I'll tell you why. Because you deserve a shout out. And that is because our podcast has received nearly 800, 800, 8-0-0 downloads. And that's awesome.

Beth Elliott 0:50

That is, but that's not because of me. That's because of the listeners and the great content that you and our guests have provided. So

Brandon Ellis 0:59

Well, let me say it this way. Beth Elliott.

Brandon Ellis 1:08

800 downloads.

Beth Elliott 1:11

All right.

Brandon Ellis 1:12

So today, we're gonna be well, first of all, we had a great

Beth Elliott 1:16

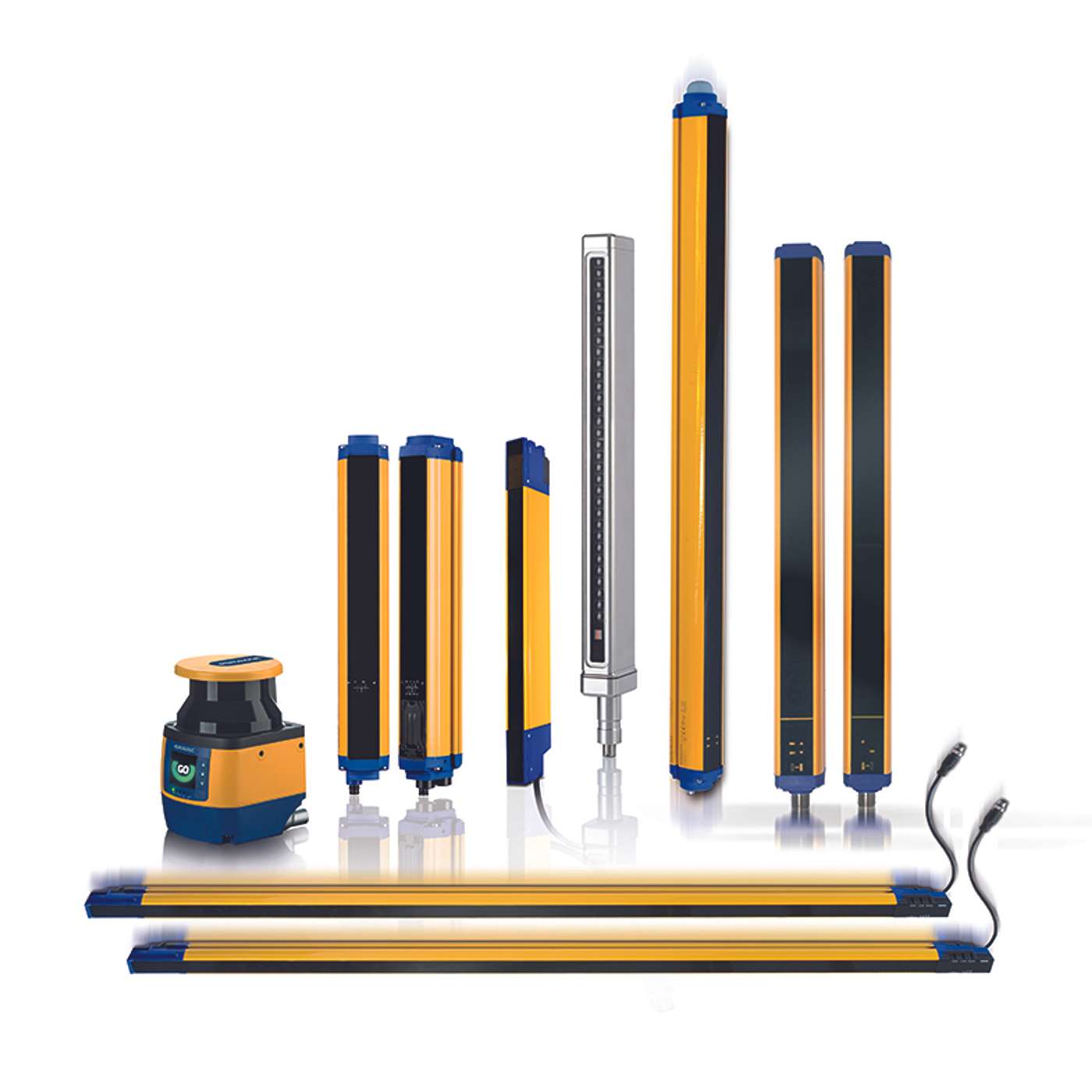

Great episode last time, the last one, we had Dave Rice with Datalogic. And he is so smart. He knows his stuff. He's a safety expert.

Brandon Ellis 1:24

And that's the polite way of saying he schooled me.

Beth Elliott 1:28

I saw your tweet on that.

Brandon Ellis 1:31

He really and that's reason I was so excited that he was going to be our guest on that episode was because I just, you know, safety is kind of safety in when I've been doing this for a long time. And it seems like for me, safety is kind of a bit of a moving target at times. Because it does come down to the organization, you want to hear more about that. And the term onus and that kind of stuff, then check out that "Industrial Automation - It Doesn't Have To... Be Unsafe" Episode, which does feature Dave Rice with Datalogic. And so, Dave is over the safety stuff. And so, I really enjoy listening and learned, I learned quite a few things from that. So hopefully, that's beneficial to our listeners. So, thank you again to Dave Rice and Datalogic for their insights, and for him being able to take place in that. But today, the new title is Beth.

Beth Elliott 2:19

Oh, today, it's called "Industrial Automation - It Doesn't Have To... Lag".

Brandon Ellis 2:25

Lag. So that's not Southern for leg?

Beth Elliott 2:31

No, it's l-a-g. What we're going to talk about is edge computing.

Brandon Ellis 2:38

Okay.

Beth Elliott 2:38

And, you know, edge computing has been around quite a while. According to Wikipedia, the origins of edge computing lie in content delivery networks that were created in the late 1990s to serve web and video content from edge servers that were deployed close to users. And in the early 2000s, there were networks, it evolved to host applications and application components at the edge servers resulting in the first commercial edge computing services that hosted applications such as dealer locator, shopping carts, real time data services, all that good stuff. So, it has been around a while. But we want to know today. What is edge computing? First of all, what is it outside of manufacturing, Brandon?

Brandon Ellis 3:26

Well, I think it's, I mean, you so you pulled that from what Wikipedia? So, if it's from Wikipedia, of course, it's true. Now actually, that is true. I mean, so edge computing, in my in my opinion, Brandology. Edge computing just means that you're doing whatever you're gonna do, you're doing it there at the point of use. The best outside of manufacturing the best scenario or no, no, the best example that I would have of that is a smartphone. If you want to know, back when we had flip phones, they just were phones. They would tell you the time, but they weren't smart. Right? And so, what made the difference between a smartphone and a just a good old, what we used to call candy bar phone and then the flip phones were part of the you know that whether it didn't fold in half, it wasn't a flip phone. But it was just a standard cellular phone. And the big difference is with smartphones, we begin to do things on the edge.

Beth Elliott 4:25

Oh

Brandon Ellis 4:26

And so, you add capability, we added capabilities. So, the smartphone actually, I think Apple, Steve Jobs would take credit for it. Because he wanted, he said, I remember watching a documentary. He said I didn't like having my cell phone in one pocket or on my belt, my cassette player or music player and another or even mp3 player on another nother loop on my belt loop, and my digital camera. And so, he combined those three. And the reason he was able to do that is because a phone became more of a smart, more intelligent device. And from that bloomed a lot of capability. And so, if you want to know the difference between edge computing and not edge computing, put your phone, not during this podcast, because it'll probably stop. But put your phone in airplane mode, and anything on there that stops is not edge based. Anything that continues to work is. So, if you have music files, mp3 files, or something like that some type of music or video that's downloaded to your phone

Beth Elliott 5:36

It's got to be downloaded to your phone.

Brandon Ellis 5:37

That's right. Then it is resident at the point of the phone, which we're going to refer to is your edge. And so, if you're on the airplane, or in airplane mode, you can still watch your videos, you can still listen to your music. But if that music is being streamed, or if that video is being streamed in and you put in airline mode, then what happens?

Beth Elliott 5:56

You don't get to see it.

Brandon Ellis 5:57

You don't get to see it, you don't get to hear it, it stops and says internet connection not found. And so those things are reliant upon a hosted cloud based or whatever some other source for their data. And so, we would not refer to those applications as being edge based. Anything that can survive on its own when disconnected from its upstairs, you know, cellular in this case, in this example, type thing is what I would consider edge based.

Beth Elliott 6:22

That's interesting. So, what is edge computing inside the manufacturing world?

Brandon Ellis 6:29

Well, that's where we refer to is Industry 4.0, smart machines, smart industry. That doesn't mean that you have to be edge based. But that means that you're all tied together. So just because I'm not edge based, meaning I can still have an industrial line that's, that's, that's using IoT type stuff, reporting data from different processes or products and things of that nature, and harvesting data from the upstairs systems in order to run. I can still have all that but if I put that line in effectively airplane mode, will it still work? Can it still work on its own? A lot of machines can, but they're not really reliant upon IoT data. They may be collecting data, and they may have an operator or a team leader or somebody coming with a check sheet and, you know, looking at the machines and taking those things off, and that's still harvesting IoT data, but it's a manual harvesting. So, if you're doing automatic, which is Industry 4.0, and your machines are providing that data, number one, that doesn't mean they have to stop, unless it's we, you know, we're afraid we're going to lose the data if we don't, you know, aren't connected. So maybe that's a grounds to shut down the production or the process cycle. But especially if you're pulling information back down, that's that cycle dependent, depends upon its dependent upon, then you'd have to stop if you lose that. And so really, what it comes down to is how, again, just like the smartphone, is it something you need to work when you're disconnected or not?

Beth Elliott 8:02

Okay, so is that what the edge is? And you kind of went over what the edge is and where the edge is?

Brandon Ellis 8:09

I said you were the edge. That's a good question. I mean, it's, you know, just like cloud, people asked me about cloud.

Beth Elliott 8:17

Yeah, where is it?

Brandon Ellis 8:18

Where's the cloud? That's a cybersecurity question. Where is it? Who else knows about it, you know, who has access to it? Know, the edge is, is defined typically, in industrial automation, industrial manufacturing, we typically define the edge again at the point of use. So just like the smartphone, where is the application needing to be used? And so, if that application can run up in the cellular cloud world, so that it only runs when you have connectivity, when you're not in airplane mode, then, then that's close enough. But if you need it to run anyway, even when you don't have cellular connection, then it needs to be edge based, and the edge is at the point of use or consumption. And so, for, for me in my smartphone, that's in my hand, that's where I am, right? Whether I'm in airplane mode or not. For a machine, it's usually we talked about OT in past podcasts, we've talked

Beth Elliott 9:15

Operational Technology

Brandon Ellis 9:16

Operational Technology. We've talked about IT.

Beth Elliott 9:18

Information Technology

Brandon Ellis 9:20

Yeah. So those are kind of the two sides within a manufacturing organization. Informational Technology is what we call the enterprise side. That's what I refer to as the upstairs systems. And then Operational Technology, that's the machines, the PLCs, the robots, that kind of stuff, and the smart devices, intelligent devices, that kind of thing, that are running on the plant floor on the point of manufacturing, production floor.

Beth Elliott 9:46

So, what are the components? What lives on the edge besides me?

Brandon Ellis 9:52

Well, in the in the outside world, I guess we all do. But

Beth Elliott 9:59

If you're not living on the edge, you're taking up space.

Brandon Ellis 10:01

That's right. Yeah. So, living on the edge. So, I just I kind of I guess it kind of alluded to them. You have devices. And then you have, well you have, you have smart devices, and then what I call intelligent devices. So, when we talk about our OT/IT layout, ISA has defined in, as far as levels of an MES or a Manufacturing Execution System, they assign levels or numbers to each component. And so, in general, level zero is people. The people that are using this machine, running the process, that kind of stuff. Level One is what we refer to as intelligent devices, and level well, and I call those smart devices. Level two is more intelligent devices, or that's your controls your PLCs, your machine controls. And then you go on, and then you cross out of OT into IT, and you have levels there. That's where you're getting to your visualization layer for all your, again, analytics, visualizations, reports, and visualizations. And then ultimately, up into your data repository, which is level four where your data centers are. That can be hosted. You know, the, you own it. Or cloud based, you rent it type situation. And so

Beth Elliott 11:18

What's the difference between a smart and an intelligent device?

Brandon Ellis 11:22

Right, so, so a smart, and this is Brandology. I call a smart device. So, a device. And I didn't mention devices. Devices are like the base, base, base. So, sensors, a standard sensor. So, for those of you who know sensors, and probably most people that are listening do, a photo proximity sensor. During the safety deal, we talked about that your garage door should have a photo sensor at the bottom. So that when the opener or closer in this case is closing the door, if someone is in, breaks the beam, it will stop and open back up. So, it won't crush anything or anybody. And it's a very basic thing, either the beam is broken, or the beams not. And if it's if it's broken, it may give a signal. If it's not broken, it may give a different signal. But it's a very Boolean device.

Beth Elliott 12:15

It's on or off

Brandon Ellis 12:16

It's either broken or not. Discrete, it's how we refer to that. And then within those same devices, you can have analog outputs, where you're measuring a temperature or distance or a pressure or something like that. And you output a signal in terms of voltage or current. That's kind of the old school way of doing that. And unfortunately, with those analog signals, we don't use them very much anymore because of interference, radio frequency, electrical noise and radio noise in the environment and stuff. It's just like static on the airwaves. If you're listening to a radio, you know what those are?

Beth Elliott 12:52

Sometimes

Brandon Ellis 12:52

AM FM. Yeah. So, you hear static if the if you're not close to the transmitter. And so that's what we refer to as interference. Well, that same static or noise can cross over to an analog voltage output. So, if that's going into a PLC, you can have a lot of fluctuation, and it's hard to be very precise. So, then we cross over to devices that are smart. That means they can talk. They're talking something, some type of a fieldbus or communications, but it's a digital protocol. That's a language. It's a computer language. And so now suddenly, that opens us up to where we can talk to these devices. They're still limited. They may still have the pass/fail outputs and the basic, analog type outputs, and that kind of stuff. But manufacturers are also giving us a way to talk intelligently to them, to say to them, or ask what is your measurement? And it tells us maybe, to a very precise, you know, decimal place. Whereas before, we just had to do averaging and kind of

Beth Elliott 13:56

Guess?

Brandon Ellis 13:56

Go, we're roughly in the. Yeah. Uh, an educated guess.

Beth Elliott 14:01

Okay, gotcha, gotcha.

Brandon Ellis 14:03

But, so, so now we're having a conversation, digitally. So, we refer to that as a smart device. But that device is it can do basic things. You may even have the capability of setting a high level or a low level and when those two, if the signal or the reading fault falls outside of that range, then an output would turn on or off or something. So, you can read what those high levels are and low levels, but it's not really programmable in terms of like a machine control, or something like that. It's not going to really influence anything else. It's more an influencer.

Beth Elliott 14:38

Oh, okay. Okay.

Brandon Ellis 14:40

When we were talking with Keary Donovan about the KPPs and KPIs and all that we talked about Key Performance Indicators and, and the data streams that feed those Key Performance Indicators. That's really what a smart device is. It's going to give you information, but it's not really going to make a decision for the next result that happens. The decision maker is a step up from that. So, the, what I call smart devices in our literature in the MES, they call that intelligent devices, but I call it smart devices. That's level one. Level Two is more intelligence in the device, which means it's a controller. So that's where your PLCs and your robot controllers and those things come into play. So, they're programmable, number one. They can communicate, but they can make decisions. So, they're logic engines. So, PLC stands for?

Beth Elliott 15:30

Programmable Logic Controller. So, it makes sense.

Brandon Ellis 15:35

I got to remember all my. PLC. I need to label my buttons on the board. So yeah, logic controller is a logic engine. So, it's logical.

Beth Elliott 15:48

Okay.

Brandon Ellis 15:48

Think Spock, from Star Trek. I mean, everything had to be logical, cause and effect. If this is a pass, we're going to do that. If this is a fail, we're going to do that. If this is in this range, we're going to act this way. If this is in that range, we're going to act that way. And so those devices all live on the edge. They're there. The question is what, from an IoT standpoint, what are they reliant upon? So that logic engine can make all the decisions for that machine and it just kicked right along with its sensors, and its communications and whatnot coming in. And you can, you can never ever connect it to the world, and it'll still

Beth Elliott 16:24

Just keep on pumping out. Okay.

Brandon Ellis 16:26

Doing it's thing. But if you're a company that's bringing about an IoT stance, why do we do IoT?

Beth Elliott 16:34

It's supposed to save money, isn't it?

Brandon Ellis 16:36

To make intelligent business decisions.

Beth Elliott 16:38

That's right, I failed.

Brandon Ellis 16:40

An IoT system is implemented primarily to make decisions, intelligent business decisions about. So, it's not just wanting to see how good we're doing or how bad we're doing, we want to make decisions based upon it. It can also be for a traceability in a workflow process, flow type management standpoint, where we want to make sure that we decrease our defect flow out, defect flow prevention steps and things of that nature to make sure that we don't make and spend money on a perfectly bad product. As soon as we know that it's bad, discard it, don't keep putting the labor, and the time and the materials into it. And so those things can influence the process. A process being a machine cycle or machine process so that the process is being controlled by those level two devices, the PLC is the machine controllers. And suddenly, if we want them, their process to be reliant upon the data associated with the product coming through, so process data versus product data, then they usually have to connect to an upstairs or some type of a centralized system. That means that if I cut communications to that upstairs system, i.e. airplane mode from the PLCs perspective, they have to stop. They can't decide if I'm allowed to run this part or if I'm not. Whatever the, whatever the reliancy is on the data associated with the product. Unless you're networking, all your PLCs together, which can be done. It's not done as commonly today, because it's a pain in the butt. And from a management standpoint, you've got to manage a lot of moving parts to make sure that any updates in this PLC are also you know, handled down here.

Beth Elliott 18:32

Oh, you got to do all of them. Make sure all of them get it.

Brandon Ellis 18:35

And then you or you got to make sure they all talk.

Beth Elliott 18:38

Oh, that's right, oh my goodness.

Brandon Ellis 18:38

And then what if you got a piece of equipment that's got a new style PLC that doesn't support communications to the old PLC or the old PLC doesn't support communications to the new PLC, and you really don't want to go back to the old days of, you know, tying I/O together. That's like Morse code. And so you want to have intelligent communications and so the easy way to do that, easier way is to tie it all together with an IoT based system, which is usually an upstairs enterprise system. If I cut the link to that IoT enterprise system, that process if it's not edge based, will stop.

Beth Elliott 19:14

Okay. Okay, so that's the big. Is that the big deal about edge computing? Is that the big deal about being on the edge? Is that you can, you don't lose that connection, or they can still keep working while they lost that connection.

Brandon Ellis 19:27

We call that Ride Thru

Beth Elliott 19:28

Okay

Brandon Ellis 19:29

So, you mentioned lag.

Beth Elliott 19:31

Yes

Brandon Ellis 19:32

Not leg, lag

Beth Elliott 19:33

Oh, we're gotta watch this cause our East Tennessee accents gonna just jump out.

Brandon Ellis 19:40

We're not, we're not really speaking East Tennessee here. We're saying lag. Lag being How fast does the system respond to you know, queries and things of that nature. And then but Ride Thru is the airplane mode or being able to basically if you're on an airplane, you put it in airplane mode to be able to still play Words with Friends.

Beth Elliott 20:01

There you go.

Brandon Ellis 20:03

I mean, that's the Ride Thru. So, it doesn't matter that you've clipped that connection, or it got clipped for you, you're still able to move along. And from a production standpoint, that's huge. And then from a lag standpoint, again, Ride Thru is one thing. But remember that this is all from the PLC or the controller, the intelligent device, the controller perspective, if that controller or process, machine process is reliant upon data associated with the product that's coming through. Now, let me lay that out real quickly. So, products coming through, we scan a barcode on it, we or read an RFID, or get some kind of a serial number or something to know, specifically, this product, is what it is. We then need to check to make sure, can we run or process this product? Again, there's no point in wasting money, in terms of time, labor, and materials if you know that this part is bad, because the previous process failed.

Beth Elliott 21:04

That's right.

Brandon Ellis 21:05

Or it didn't go through it at all, or something like that. So, if that PLC has got to ask before it runs. So, the operator grabs the part, scans it, sets it in the nest, hits the start button. And they expect that machine to run or that machine to tell them no, in a fairly quick way. Production managers also want that to happen in a fairly quick way. If they're going to an upstairs system or an offsite system or even a cloud-based system, there is the issue of lag. How, the delay, how long between the time that the machine asked, Can I run this, to the time it gets a response. The further it has to go, the more bandwidth issues there are those kind of things. And it can be an issue. And it can, I've seen it add at minimum a second to your cycle time.

Beth Elliott 21:53

That doesn't sound like a lot, but it adds up, doesn't it?

Brandon Ellis 21:55

That adds up a lot. Lot. Lot. If you can take a second out of your cycle time. I mean, every manufacturing and production engineer and production manager should be listening to me right now. They just perked up because your - Wait a minute, I can take a second out? Well, I don't know. I mean, if it's if you're lags a second, possibly by going to an edge-based system, you can take out potentially a second. Definitely you could take out 500 milliseconds, probably and anything less than 500 milliseconds, most operators and most cycle time counters can't feel. But still a second is huge. Yes. So, two seconds, three seconds, 10 seconds is even more huge. And so those kind of things. That's what we call lag. That's the network lag. It's just because, you know, the network may just not be able to handle the bandwidth, there may be tons and tons and tons of communications going on. The server may be just getting nailed with all kinds of stuff, because one server, one data server, one data center is trying to handle all these different line requests at the same time, and also run reports and all the things that it's going to do. So being able to push that processing power out to the edge, which is the line side, saves us in lag. It lets us Ride Thru and provides all kinds of benefits.

Beth Elliott 22:36

That's cool. So, what's the difference between you'd mentioned the product data and the process data? What's the difference between those? And how do they relate to the edge-based computing?

Brandon Ellis 23:21

Well, I mean product data, it has to do with the product. Usually, we refer to that as traceability and things of that nature. So, you have to be able to trace your product in some way. The process data really has to do with the machine. So, when we're when we talk about, we have in past podcasts talking about, again KPIs, Key Performance Indicators, Overall Equipment Effectiveness, OEE, Overall Availability, OA, those types of things, that all has to do with the machine, the process. That's just saying how well is the machine running? How often does it break? There may be a quality aspect as far as scrap, you know, how often it produces defective parts. But usually, they're, they, that's not in the equation for most, most folks. Usually, it's just uptime, downtime. When's it running? When's it not running? Then you also get into waiting. When is it in a starved condition and that kind of stuff? And so as far as your production planning as far as moving, maximizing your, the amount of widgets that you make. Remember we talked about that? What was the term for the when you, the best? We were. Oh, what was the term for the best? It's left me. My mind's gone blank. The best time, the most you could make possibly. It was a

Beth Elliott 24:38

Is that Six Sigma? No

Brandon Ellis 24:40

No, no, no. I'll it'll come to me in a minute. Anyway. No, it won't. It won't come to me. Go listen to that episode.

Beth Elliott 24:47

I'll have to have a link in the show notes for it.

Brandon Ellis 24:51

It wasn't team. Was it team?

Beth Elliott 24:53

TEEP

Brandon Ellis 24:54

TEEP. That's it. That's right, yeah.

Beth Elliott 24:57

Total effect, no

Brandon Ellis 24:58

Total total. Yeah, I can't remember the

Beth Elliott 25:02

Equipment effectiveness performance?

Brandon Ellis 25:04

It had to do with performance. Basically, your TEEP says, if you were able to run 24 hours a day, seven days a week, with no bottlenecks, nothing, what's the most you could do? And because there's some days, no, no, I said that wrong. If you're able to run the maximum for your production cycle, which may be seven days a week, it may be five days a week, it may be 10 hours a day, it may be 30 hours a day, subtracting out

Beth Elliott 25:29

Thirty hours a day?

Brandon Ellis 25:30

Okay. So, 30 hours a week is what I meant or shift, 30 hours a shift. Okay, so all right, I deserve that. Okay, so your shifts, your production shifts, those kind of things, if you were able to run all your shifts with no downtime, what's the best case scenario? So that comes in production planning, and those kind of things, because you got to take out for breaks, lunches, time off, holidays, those kind of things, and then you begin. So that's what you're, that's your maximum best ever kind of thing. And so that comes down to production planning. So that's all process data driven. Process data driven, it doesn't really take into effect, it looks at how the machines running, it doesn't take into effect, whether or not the machine is shooting out bad parts.

Beth Elliott 26:19

Gotcha.

Brandon Ellis 26:20

So that's where product data comes into play. And we actually, I was having a conversation with a customer the other day, and I praised them, because they, they, it was great, because they were like, maybe we're doing this wrong, maybe we're looking at this wrong. But what they were saying was, we feel like that we need to look at our process data and combine it with our product data to know is our process doing what it's supposed to do. Is it a process issue that's causing bad parts? So, you got to look at the settings of the process and all the things that were being used, and then look at what comes out. And the difference was, they wouldn't find out until later, down the line, down the process, whether this part was good or bad. So, they had to kind of look back. But unless you can trace the product, to know this product was made, and tie that to the process data under these settings on the machine. Unless you can tie those two together, you're only getting one side of the coin, you really need to overlay it. And so, I was telling them, that's exactly what you need to do is to be able to take both of those things. And so many times companies will spend a lot of money to get one - OEE, OA.

Beth Elliott 27:34

Oh, okay.

Brandon Ellis 27:35

That type of stuff. All right, this is our uptime. This is our downtime. This is where we're starved. This machine, the cycle time on this machine doesn't get the parts through fast enough, so we build up a bottleneck and that kind of stuff. But it really comes down to both the product data and the process data if you're going to look at the whole picture. And that's what they were asking me Is this right? And I was just like, This is exactly right! So, it was an exciting time. But that's the difference between product data and process data. And again, edge computing is beneficial when the process itself, not the data, but the process, whether or not it should run or how it should run is reliant upon the product and the data stream that follows it.

Beth Elliott 28:18

Okay. All right. Well, can edge computing be used in new applications? Or does it or does it have to be added to existing architecture? What's How can it be? How can manufacturers utilize it?

Brandon Ellis 28:32

So, today's sponsor is elliTek. Honestly, that's a great question. We get that question a lot. And we've talked about that in the past with, we were talking about IoT in our IoT podcast, and we've done a few of them, but It Doesn't Have To Be.

Beth Elliott 28:49

Oh, it was the IoT - It Doesn't Have To Be Overwhelming.

Brandon Ellis 28:52

Overwhelming. That's right. Yeah. So, we were and we were talking about the acronyms and everything in that. I think that was the acronym one.

Beth Elliott 28:58

There's always acronyms.

Brandon Ellis 29:00

So IIoTA is not an acronym. It is an acronym, Industrial Internet of Things Appliance. It's actually a product that's manufactured by elliTek. IIoTA. And so, we've got two forms of that. And, and, and customers use it in different ways. But one of the things that we do when we develop the IIoTA is we see it as important as it is to support the cutting edge, as far as communications, and communications is really where we're at. And if you listen that podcast, that's what you're going to hear me say, communications. If you can't communicate to it, you're not getting what you need. Go back to the basic sensor, off and on is a type of communications, but it's not the best. And we can do another podcast on that because really what it comes down to is if your sensor tells you it's a pass or good how does it really mean how

Beth Elliott 29:56

What's good mean?

Brandon Ellis 29:57

What's good mean? What under what criteria did you judge a good? Because if that sensor got modified with the settings or something like that. We talked about sensors can do high level and low level, and if it's in this range, we give one output. But what if someone inadvertently or on purposely changed your range, and now all of a sudden, you're getting a good output for something that's not really good. If you don't know what the high level is, and the low level is, you have no means of really knowing if it's a good. And so, communication makes that possible to be able to say, what was your high level, what was your low level, and then tell me what you said pass or fail. To be able to get that information lets you see the whole picture. Because if you find that the high level is way higher than it should have been, then in the value is above that, where it should have been, then that really should have been a fail. And so, a pass is not a pass. So that's the kind of stuff. So existing applications communication, so getting back to that. Communications is everything. We pride ourselves with our IIoTA and Data Commander products. And of course, it's all IIoTA now and Data Commanders is our old platform, but we pride ourselves on being able to talk to the old, as well as the new. Our mission statement is to empower our customers. And the best way we felt to do that was to make it so that to do IoT, you don't have to go out and retrofit your entire line or buy all new equipment. But if you do, we can talk to that too. And so that's really where it comes down to. And then we have different flavors now of the IIoTA where we have more of an end user line, total total line version, line side, edge-based version, that actually does our Workflow Manager and all that kind of stuff. And then we have our MiNi, which if it's new equipment, customers can either specify that their machine builders put these in, we can work with you on that. But it comes setup, it can come set up and ready to go to be able to deliver the data, and the dashboard tools, and those kind of things are all built into that. But anyway, not getting into all that. It's not a. As passionate as I am, it's not a sales podcast. But I do have said if I feel like it's a good thing, I'm going to talk about it. And not just because I invented it, I invented it because it was needed. And a lot of people have used it. And so, for us, it can be added to both new or existing in most cases. Not everybody.

Beth Elliott 32:24

Not everybody.

Brandon Ellis 32:25

Not all the solutions that are out there that are close to ours.

Beth Elliott 32:29

Okay. Okay. So, what about manufacturers that can't buy, or they won't buy new equipment? How can they use edge computing so they can remain competitive? Maybe an example for the listeners? Can you tell us about a project along those lines?

Brandon Ellis 32:44

Oh, sure. So, to be more competitive, so first of all, why would they be asked? Well, why would they want to do edge computing? We talked about that Ride Thru and lag,

Beth Elliott 32:54

Save the bandwidth.

Brandon Ellis 32:55

A lot of times, we have some customers that they are building stuff that's being sold to someone else supplying to a larger customer, their customer, our customer's customer, and the customer's customer for either quality reasons or, or something might require some of these systems to be put in place. And so, our systems give them the capability to meet those requirements at an affordable in an affordable way, largely because they're easy to use. And we can train them to do themselves, or we can help them with it in shorter amount of time than most. And then also the hardware is affordable. But as far as an example of how this was done, it wasn't so much because they were being asked to do it, it was because they had an internal pain, an internal pain point that was going on. What it really came down to was their process required that the process at the point of, at the edge, each process had to be reliant upon data in a upstairs system. This upstairs system was actually not upstairs, it was upstairs in another building in another state.

Beth Elliott 34:04

Oh, wow. Okay.

Brandon Ellis 34:05

And so, the connectivity was through an internet provider, a national internet provider, just like you would have, you know, in your business or your home or anything like that. So you would pay for Internet access. The problem was at this particular plant, they had a problem with unexpected outages.

Beth Elliott 34:26

Okay. Well, it would just stop, wouldn't it?

Brandon Ellis 34:27

It would just stop because airplane mode.

Beth Elliott 34:32

Yeah.

Brandon Ellis 34:33

And so that's a perfect example of why you would need edge-based computing. And so, we were able to go in with, in our case the IIoTA, and stand it up and on the edge base side and help them with that and, and make that work and a lot of different ways. And it was it was a, it was a really nice and elegant solution.

Beth Elliott 34:51

So, what about, the were there already, was there, what other equipment was involved? Because it sounds like it was already existing, the equipment.

Brandon Ellis 34:59

It was existing. So, I don't want to get into their process, so I'm going to pretend like

Beth Elliott 35:04

Generalize it. We're almost at Valentine's Day, so I think your vase example is good.

Brandon Ellis 35:09

Flowers. We're going to do flower arrange, floral arrangements. So, let's, let's assume that this production line that had multiple places and stops where associates were along the same line. And so, the way that their process worked originally was each and each pallet has a vase on it, so everything gets a vase.

Beth Elliott 35:34

okay

Brandon Ellis 35:35

But what goes inside of the vase. Am I saying that right, vase?

Beth Elliott 35:40

Vase, v-a-s-e.

Brandon Ellis 35:44

What goes inside, what goes inside of, of this container that holds flowers is, it could be anything, I mean, it's gonna be a known. It's not there, you know, any exotic flower. It's a selection of flowers. They're pre-selected but based upon what the configuration is of this arrangement, will decide what flowers it gets, what colors of flowers, those kind of things. And so, at each station, some of those things will be added. So maybe at this station, I'm the rose station. So, I've got all kinds of white roses, yellow roses, red roses, long stem roses, all this kind of stuff. But roses. That's what I have. So, when this comes about my station, I need to know which roses go in. And how many. And maybe in what

Beth Elliott 36:35

Is there an order?

Brandon Ellis 36:36

Order. Yeah. I've never been a florist. I've looked at flowers before but anyway. And then at the next station is the carnations. Is that a thing?

Beth Elliott 36:47

Yes.

Brandon Ellis 36:47

Carnation station, and then the next one is?

Beth Elliott 36:50

Oh, the greenery. I would think. I don't know.

Brandon Ellis 36:54

Isn't there something called. Something about a baby.

Beth Elliott 36:57

Oh, baby's breath. Okay. Yeah, yes, that would go in there.

Brandon Ellis 37:00

The baby's breath station, I don't know how many forms of baby's breath there are but good breath and bad breath anyway. So, you have these different stations. And so, the way that they did this initially was at the very first station, that person was in charge of setting the container onto the thing. And then they scan the container, or the order that's associated with the container. And it would, they had a printer that would print out 8 1/2 by 11 sheet of all the things that were supposed to go in at each station. And so, based upon which station you were, they would call that a traveler. That's pretty common. It would run along with the, the, the, in this case, it would call it a pallet that the containers on, and the person at that point would pick it up, look at it, go to their section, okay, it needs, you know, good baby breath instead of bad baby breath or whatever. And they would do that, right. And then they send it on down the line.

Beth Elliott 37:45

Okay

Brandon Ellis 37:46

And if it said, No, baby's breath, then they just send it on down the line. But they have to go to their section, they have to look. So, a couple things, couple of things bothered them about that. Number one, they're blowing through some paper from, from a, from a green standpoint, they're, they're laying out some trees. Number two, in the summertime, a lot of times it would get warm in the place. And so, fans would go into use, and a lot of times those travelers would turn into confetti, and just, you know, everywhere. And so, they were always chasing these kind of pain points. And God forbid that, you know, sometimes it'd get blown off of one and they put it on the wrong one, or sometimes they wouldn't get returned back to the right, right place or it'd get lost altogether, or something like that. And so, how do we solve that? Well, first of all, the printer was connecting to, when they would scan it, the scanner would go up to the main system in another state.

Beth Elliott 38:51

Okay,

Brandon Ellis 38:52

That main system would look at it, evaluate it, and go through all the data, figure out what it needed to be on the configuration and print out the eight and a half by 11. If that link was

Beth Elliott 39:04

Severed?

Brandon Ellis 39:04

Severed, it would stop. Production stopped. So that was bad.

Beth Elliott 39:09

Yeah.

Brandon Ellis 39:09

Number two, if the order, you know, now, the upstairs system is communicating to the associates by writing it a letter, writing it a note. I mean, that's what a printer is. Right? So, it's writing it a note. And if you lose the note, you're done. So, these are some of the basic pain points that they were dealing with just causing some quite a bit of downtime. So, they, we ended up setting an IIoTA on the line, we would sync up. So, the obstacles they had to face.

Beth Elliott 39:40

Yes,

Brandon Ellis 39:41

Yeah, let's go through those. So, connectivity, you have to be able to connect to in their case, something's gonna have to be able to connect to the upstairs, the out of state database, pull the information down, connect to the scanners or the pallets or somehow identify them and the system that runs that which is a PLC base. And then you're gonna have to have the data, somehow sync up the data with the upstairs system in case the thing goes offline, because you want to be edge based, you've got this vision, this traveler, so you've got to create some way of, we want to reduce the carbon footprint, get rid of the paper, and also reduce the loss factor. So, we need to visualize this thing at each station. And then I guess, we need to Ride Thru if that connection is severed. And so that's kind of the data sync. So, these are all the things that we had to do. And we did it with an IIoTA, used our dashboard, our onboard dashboard tools to build all the visualizations for the traveler. So, every time at each station, they would they had RFIDs on the pallets that was going to the existing PLC system, we were sinking up with the existing database.

Beth Elliott 40:53

Okay.

Brandon Ellis 40:54

So other than the screens, the video screens at each station, which took the place of the paper and the IIoTA, that's the only the only hardware that had to be added.

Beth Elliott 41:05

Okay, okay, wow.

Brandon Ellis 41:07

Because we could connect to their existing database server with no problem. We could connect to their PLC and talk to it natively with no problem.

Beth Elliott 41:14

So elliTek's engineers didn't have any problems with this edge based computing system, IoT system that they put in?

Brandon Ellis 41:21

No, we didn't. Now fast, you know, backtrack to back before IIoTA in my life I wouldn't have taken the job.

Beth Elliott 41:28

Okay. Cuz How, How else could they have done that?

Brandon Ellis 41:31

I've been trying to put PCs on the floor, then we would have all kinds of cybersecurity issues. Ours is not PC based. So, we don't have the cybersecurity. We've got good solid hardware-based isolation, all those things that we do that I would not have, as an integrator wanted to take on. Now that's probably different some today. We've gotten better at that stuff, it's a bit more commonplace. But still, yeah, we actually were able to prove it all out before they spent $1.

Beth Elliott 42:01

Wow, wow. So, what were some of the benefits? And I think we kind of know, the positive aspects. You kind of went over that, but

Brandon Ellis 42:10

Well, it worked.

Beth Elliott 42:11

Yeah, that's awesome.

Brandon Ellis 42:13

It worked. From our vantage point, it was fun. We had we enjoyed doing the project. Because all the tools were there. We get to grin when the customers say can we do this? We're like, Yes. Yes, we can, and as a matter of fact, it's done right now. We just did it, you know, that kind of thing. We're saving trees, I guess. And then what the production time we talked about the lag, and then just that general downtime went away, if it went

Beth Elliott 42:43

Because they weren't losing the connectivity anymore.

Brandon Ellis 42:45

Right. Because we would sync up.

Beth Elliott 42:46

The Ride Thru.

Brandon Ellis 42:47

And so again, in my scenario, there's set configurations for flowers. And so, if we have that data, we could we pieced it together there on the edge with within the IIoTA. Populated the screens that needed to be populated based upon, you know, actively based upon the RFIDs of the of the pallets. And so, when the PLC would say this station has this RFID we would boom, do a quick lookup, very, very little lag because we're right there on the line. We would populate those, those dashboards based upon which position. One of our engineers actually did the layout. And it looked, he built it exactly like the piece of paper. So, it just looked like the piece of paper was changing.

Beth Elliott 43:35

So, the associates didn't really have to adjust too much.

Brandon Ellis 43:38

That's right. Well, we but he did narrow it down to the section.

Beth Elliott 43:42

Oh, okay. So, they didn't have to see everything that went through.

Brandon Ellis 43:46

He actually also added added, they could push a button, it was a touchscreen, they could push a button and go to an exploded version of the floral arrangement. That was a fixed picture, but it was tied together. Just to say if it's this station, and then this is what it looks like. So anyway, those are all pre-loaded things. But anyway, we save you know, we saved a lot of production time. There was a cost reduction, not just in the production time because of lag. But they actually had two providers.

Beth Elliott 44:17

Oh, two internet service providers?

Brandon Ellis 44:19

Yeah.

Beth Elliott 44:19

Oh, cuz they the first one wasn't very

Brandon Ellis 44:22

Well, if one they both weren't great based upon their geography, they're both weren't great. So, two was better than one. And if one went down, it would fall fell over to the vice versa. And so, they got to, they still needed one, but they got to eliminate the other one. I don't know what that cost was, but I know what my internet providing cost is not cheap. So, they got they had two, so they got to eliminate that. And then you know, I would say you know, true to our mission statement, we empowered them because we were using our drag and drop dashboard builder. So, when we when We built, our engineer built the traveler, if you will, the visual traveler. He used our drag and drop dashboard. So, they could go in and modify that if they wanted. If they wanted to change it and resize it or put in new fields or whatever they could do that we trained them on how to do it. It's not. I mean, we're talking about two hours. Show them how to do this. Oh, that's pretty good. Well, you try. Okay, yeah, I got it. Okay. That's the kind of thing and then we you know, just typical things like, showing them how to use the troubleshooting tools that are built in general stuff that we try and train on our product all the time. Again, I'm not trying to make this about our product, but we did use our product and Doggone it, it worked great. It checked all the boxes, and it did exactly what it was designed to do. And so, it was it gave them an edge-based solution.

Beth Elliott 45:47

Yeah, yeah. So, what advice would you have for manufacturers that are looking to do more edge computing? What should they look out for?

Brandon Ellis 45:55

Oh, I was gonna say use IIoTA. I thought you thought you were teeing it up. IIoTA is the way. No, IIoTA is fantastic. But what do they need to look out for? You know, I've been on my soapbox before, when you've asked me about that. And if I'm being totally transparent, I would say Watch out for the bill of goods sale, the sales fodder, the marketing fodder. We have just seen, I've talked to so many people been more of a grief counselor at times, because they made decisions for various reasons. Most the time they didn't, you know, it's always I wish we knew you then. But they had spent a lot of money, made some great big investments, and didn't get what they thought they were gonna get. So, I guess what I would say is, don't. And in those cases, a lot of times they were, they were told they were going to get all this fantastic stuff for a not cheap, but still compared to what they were saying a great price, too good to be true price. So, don't let the dollar signs or lack thereof, cause you to hear what you want to hear. Don't and then then everybody can make a fantastic looking dashboard. The arts and crafts, man, they get you going and seeing something and think man, mine could look that way. And not understanding all the stuff that's behind it, that really has to be done behind it. Now we take care of a lot of that stuff. But I'm just saying in general, there's a lot of stuff going on. It's built into a lot of our product, but it's everybody claims it's built in. Don't let that let you see what you want to see. Ask questions. Take some time. And for us, especially if it's a, if it's a large investment, we're gonna try to prove it. We're gonna try and prove it out. We're gonna we want to make sure, honestly, I tell people all the time, our reputation is worth more than any sale we could get. And so, we're going to do everything we can do to make sure that ours is the right solution for you. And if ever if other people aren't willing to do that, then walk away.

Beth Elliott 48:05

Just, yeah, at least question it.

Brandon Ellis 48:07

Yeah. Think better of it. I mean, we all need to succeed, and especially in this United States, but even in other countries, everybody needs to succeed for the production and the people that are working for them. And if you don't succeed, then your company doesn't succeed. If your company doesn't succeed, people lose their jobs and their livelihood. And we don't want that.

Beth Elliott 48:31

No. And you've seen the five stages of IIoTA grief haven't ya, or not IIoTA but five stages of industrial IoT grief. Yeah,

Brandon Ellis 48:40

You did. You should post that again. I can't remember what they are. But it was something like it ultimately ends up in there's no point.

Beth Elliott 48:49

Yeah, just give up.

Brandon Ellis 48:50

Pull the plug on it. Let's go back to Tic sheets and that kind of thing.

Beth Elliott 48:55

And you've seen that happen, haven't you?

Brandon Ellis 48:56

I have we there's it's disappointing. A lot of companies that there are a lot of companies out there who have fallen victim to, I'm just gonna call it marketing fodder, sales fodder. Somebody came in and sold them on all this stuff. They spent all the money and especially your small to medium enterprise type companies. But even the large companies, I've seen some large companies that they totally pulled the plug on the whole thing. It wasn't our system. Now don't get me wrong, they weren't using IIoTA. If they were using IIoTA, I would've made doggone sure everything worked perfectly if I had to personally go out there. But they were using other systems that gone other directions and management just finally got to the point where they're just like this, this is just a black hole, or it's not giving us the data that we want, or we've got all this that's the new thing. We've got all this data, and we are certain that a large percentage of it is junk. And what, now we're, they're trying to find software's or something to actually go in and do all the data mining and the analytics to try and separate the wheat from the chaff, to separate the bad from the good. And the fact is, is if you have one suspect piece of data, all the data is really suspect. One bad apple spoils a bunch. Now, it's not always the case. But we all would rather know that our data is accurate and, and reliable. And I've seen these systems where they either it was unreliable, because it was harvested incorrectly or it's unreliable because it can be changed after the fact or things of that nature. And it's unfortunate, it's unfortunate. And but I get it. I mean, at some point, you finally just like, you know what we were doing great when we're doing the tic sheets. Let's just go back to that. And probably you should. Let the wounds kind of heal. Let Time, Time heals all things. But when you're ready to give it a shot again, I would just ask questions and be thorough.

Beth Elliott 50:55

Yeah, yeah. What kind of questions should they start with?

Brandon Ellis 50:59

The first question I would, I would ask is, how are you going to do it? What's your plan? I've got all these systems in here. How are you going to connect to them? Not Oh, yeah. we'll, we'll get the data. No, how?

Beth Elliott 51:10

Yeah, okay.

Brandon Ellis 51:12

Because if you're going to stand up a server, whether it be cloud based, or here or whatever, and say, okay, we can get all the data. Okay, get it. Well, no, wait a second, your people are going to, you're going to have to go out and contract all these people to run fiber out to all your machines, to put switches in, to put all this kind. Whoa, that's not getting the data. You've created a repository, but you haven't gotten the data. You told me or indicated that you were going to get the data. So let it be gotten. And if they can't, then walk away. I mean, see it, show me the plan. Show me how you're going to do it. And then tell me exactly. Look, here's the quick step, if you can't communicate with the machine, in some way, shape, or form, and I'll define that quickly. Talk to the PLC, talk to the controller, or if you can't talk to the controller. A lot of machines out there, they're closed systems, you cannot talk to them. Can you do an EKG method? And now elliTek is superb at EKG methods. That's where we're putting sensors on the things and we are able to infer things about the process. Now, not necessarily the product, but sometimes. We have to get creative. But it's the difference between putting sensors on your body for an EKG to know what your hearts doing versus cutting your chest open and looking at what your hearts doing. And so, if you can't just communicate with a PLC, you can do an EKG method. But there is a means you've got to be able to pull that data, to harvest data. That's it's got to happen. And so, any system needs to have a clear and concise way of getting that data from the machines, OT. If you're going to put it in a database server somewhere, a cloud, upstairs, whatever, edge based, you are going to need to be able to communicate to that database server. So how? And it's going to not happen, you know, magically, nobody uses magic not yet. It might be wirelessly. It might be cellularly if you don't mind,

Beth Elliott 53:16

The risk

Brandon Ellis 53:17

The risk of cyber security vectors. But there's got to be a way. What is it?

Beth Elliott 53:24

And show me

Brandon Ellis 53:24

Show me. I mean, you don't necessarily. I'm not saying go out, make them prove it, make them do it all for free, and then it's not, if it doesn't work, send them out. Put it on paper. Show me. Make a diagram. How is this going to connect together? What can I expect? And then who's responsible for each one of the lines on that piece of paper? If you drew it out, if you draw a machine, you draw a database, you draw something in between, you draw your dashboards, all those kind of things, and you're connecting those all by lines, How are those lines connecting? What is that? What's that line represent? And then who's responsible for making, making that line come into existence? Who's responsible for purchasing the TV to display it? Who's responsible for hanging it? Getting power to it? Who's responsible for creating the data tables and, and whatnot in the data in the data table in the database for storing it? Who's responsible for setting up the communications with the database if they're stored procedures or things where there's some intelligence on the database side? So maybe we're saying this is the part number and expecting it to respond with Yes, you can run or no, you can't. Who's responsible for creating that? Because that's a program. Yeah, if it's on our IIoTA, that's built in with our Workflow Manager. But if you're doing it on your upstairs system, which many people will do or on a server a software, who is creating that? It has to be created because your process is different than everybody else's process and there's nobody that's going to sell an off the shelf software product that works for everyone's process the same.

Beth Elliott 54:56

Not everything is

Brandon Ellis 54:58

Unless everybody in the entire planet starts making the exact same prod product the exact same way. And so, these are things that everybody thinks about and knows. It's not, it's not earth shattering. But sometimes when we see stuff and we see a price, or we see an opportunity to improve our process, or, or if we're being leaned on by upper management, or, you know, the board of directors or investors or whatever, or even outside customers to show us this show is this, and you don't really have it in the budget to do and somebody comes to you with a great price, or they show you a dashboard, or some kind of visualization that just looks really good, then then it's easy for us as human beings to begin to hear and see what we want to hear and see. And on the backside, you're gonna realize the difference, and I would rather you not have that experience.

Beth Elliott 55:49

Yeah. So, what do you what. Do you have anything else you want to add to that?

Brandon Ellis 55:55

Well, since I have kind of sold the IIoTA during this podcast, even though I wasn't supposed to. Let me tell you about something. Our web demo, if you would like to have a demonstration of the IIoTA MES Gateway, call us. I'll make sure that we set it up and we can demonstrate what it can do for you.

Beth Elliott 56:13

That's right. Or they could email I think it's free demo.

Brandon Ellis 56:17

Is it? FreeDemo@elliTek.com

Beth Elliott 56:19

Yeah, FreeDemo@elliTek.com. It looks weird spelled out. It's like freedem-o.

Brandon Ellis 56:29

Freedemo@ellitek.com. Yeah, seriously, if you if you are looking at this kind of stuff, and especially if you had a bad experience, you want to talk a little bit about it and what we would do, certainly we'd love to share with you.

Beth Elliott 56:40

Yeah, for sure. And next up for the, our next episode, we're gonna have another special guest.

Brandon Ellis 56:47

Special guest. Oh, I've been looking for that one. Let's try that other one. No, not that one. I know what that one is. Special guests

Beth Elliott 56:56

That's right. It's going to be Morgan Everett with the Red Nation Robotics team over at our local high school here in Knoxville, Tennessee, Halls High School, the Halls Red Devils. So

Brandon Ellis 57:08

Morgan Everett, everybody knows him as Everett. That's his last name. So, I always say Morgan and that throws people off. Everett is fantastic. What he and those and the students

Beth Elliott 57:21

They are fantastic

Brandon Ellis 57:23

I've been blown away with the stuff that they've done and what they pulled off over there. And with COVID I haven't had all the opportunity to get over there. It's affected every high school and in probably the world but definitely in the United States. And it has grossly affected FIRST robotics. You know, last year we were working with sponsored them, but I was they did so great. They won worlds.

Beth Elliott 57:47

That's amazing.

Brandon Ellis 57:48

And then COVID. And it kind of ripped. No, it didn't kind of, it yanked the rug out from under them. But it's amazing to see how they've made the best out of it. How they continue to do that. Unfortunately, the competitions have, as live competitions, I think he told me the other day he shared with me when I saw him, that they've been cancelled, modified to virtual, I guess. So, I'd like to hear him tell us a little bit about how they're gonna be virtual. But just some of the fantastic things that they're doing over there. And it's a great program FIRST robotics. I'm sure a lot of people are familiar with it. And certainly it's of course, it's part of the STEM education movement and that kind of thing. But yeah, FIRST Robotics at Halls High School. Shout out guys. You're doing great.

Beth Elliott 58:31

Yay. Yay. Wait.

Brandon Ellis 58:33

Oh,

Beth Elliott 58:33

Oh No, I pressed the wrong button!

Brandon Ellis 58:38

Beth did that.

Beth Elliott 58:39

Red Nation Robotics.

Brandon Ellis 58:41

Red Nation Robotics, Halls, Tennessee. Nope, Halls Fountain City, Tennessee, here in East Tennessee. Yeah, so we're looking forward to that. That's gonna be a lot of fun. What else?

Beth Elliott 58:51

I think that's about it.

Brandon Ellis 58:53

Rate n Review.

Beth Elliott 58:54

That's right, rate n review. Just you can find elliTek we've got all the podcasts on our website now. It's elliTek e-l-l-i-T-e-k.com slash podcast. And you can see them all there. And you could subscribe to the RSS feed there. And just leave us your comments. And let us know what we can do to empower you in your career.

Brandon Ellis 59:16

So, and also let us know if you got some topics that you'd like to hear about. If you've got some problems, you'd like to see a solve, solve to or how I think I would solve it, or we would solve it as from our vantage point. Follow us. Rate us. Review us. Subscribe to us. Tweet us. Tweet us, tweeted, and visit our website. Give us a call 865-409-1555.

Beth Elliott 59:42

555

Brandon Ellis 59:44

1555, that's right. All of a sudden it didn't sound right. Guys, I'm Brandon Ellis. This is Beth Elliott. "Industrial Automation - Doesn't Have To"

Beth Elliott 59:55

It Doesn't Have To Lag.

Brandon Ellis 59:56

It Doesn't Have To Lag. Hey, see ya Beth.

Transcribed by https://otter.ai

Podcasts we love

Check out these other fine podcasts recommended by us, not an algorithm.

Digitalization Tech Talks

Siemens

Talking Industrial Automation

Lisa Richter